|

|

|

Small Recycling Systems

A recycling system is an enclosed system where the only water replacement is the water lost to evaporation and cleaning.

. Recycling systems in AQUACULTURE

have stirred a great deal of interest in the AQUACULTURE

community in the United States and other parts of the world.

Given enough resources, there is little doubt that most species

of fish grown in ponds, floating net pens, or raceways could be

reared in commercial scale recycling systems.

There are four major advantages in using recycling AQUACULTURE

systems:

1. Low water requirements, low land requirements.

2. The ability to control water temperature.

3. The ability to control water quality and.

4. Independence from the adverse weather conditions

Low Water Requirements

A properly designed and operating recycling system requires a

minimum daily input of water, usually less than 5-10% of the

total system volume. This permits the construction of AQUACULTURE

facilities in areas where ground water is limited and even allows

the construction of facilities in urban areas using

de-chlorinated municipal water.

Low Land Requirements

Fish in recycling systems must be reared in tanks or raceways at

very high densities to make the production system cost effective.

For example, a recycling system is often designed to hold about

0.5 pounds of fish per gallon of tank volume.

Control of Water

Temperature

The low water requirement of a recycling system opens up the

possibility of economically controlling the water temperature.

This permits the water temperature to be maintained at the

optimum level to maximizing production and allowing rapid

turnover of the product. Control of the temperature also allows

the us to produce species, which could not normally be raised in

a given geographic area (shrimp in Chicago or Trout in Hawaii).

With recycling systems we have the opportunity to directly

control water quality. Water quality parameters such as dissolved

oxygen can be maintained at optimum levels, improving the growth

rate and reducing stress and minimize the potential for diseases.

In addition, the fish are isolated from potential environmental

contaminants, thus guaranteeing the highest quality product for

the market.

Independence from Weather

By rearing fish in indoor recycling systems, we are no longer

limited by weather conditions.

A sudden cold spell can wipe out a year's production by killing

larval fish or disrupting the normal spawning of brood fish.

Having the fish indoors also permits the harvest of fish when bad

weather would stop pond operations.

All AQUACULTURE production systems must provide a suitable environment to promote the growth of the aquatic crop. Critical environmental parameters include the concentrations of dissolved oxygen, un-ionized ammonia nitrogen, nitrite nitrogen, and carbon dioxide in the water. Other important parameters include nitrate concentration, pH, and alkalinity levels within the system. To produce fish in a cost effective manner, production systems must capable of maintaining proper levels of these water quality variables during periods of rapid fish growth. To provide for such growth, fish are fed high protein pelted diets at rates ranging from 1.5% to 15% of their body weight per day depending upon their size and species (15% for juveniles, 1.5% for grow out). Feeding rate, feed composition, fish metabolic rate, and quantity of wasted feed has a major detrimental impact on tank water quality. As pelted feeds are introduced into the culture system, they are either consumed by the fish or left to decompose in the system. The By-products of fish metabolism, include carbon dioxide, ammonia nitrogen, and fecal solids. If uneaten feed and metabolic by-products are left in the system, they will generate additional carbon dioxide and ammonia nitrogen, reduce the oxygen content of the water and have a direct detrimental impact on the health of the cultured product.

In tanks, production intensity

must be very high to make the production system cost effective.

As a result the natural biological filtration capacity of the

system is exceeded and the producer must rely upon the flow of

water through the tanks to wash out the by-products of fish

metabolism and wasted feed. Additionally, the

oxygen concentration within the tank must be maintained through

artificial aeration either with atmospheric

oxygen (air) or pure gaseous oxygen injection.

The rate of water exchange required to maintain good water quality in tanks is best described using an example. Assume that a 5,000-gallon production tank is to be maintained at a culture density of 0.5 pounds of fish per gallon of tank volume. If the 2,500 pounds of fish are fed a 32% protein feed at a rate of 1.5% of their body weight per day, then 37.5 Ibs of feed would produce approximately 1.1 pounds of ammonia nitrogen per day (approximately 3% of the feed becomes ammonia nitrogen). Additionally, if the ammonia nitrogen concentration in the tank is to be maintained at 1.0 mg/l. then a mass balance calculation on ammonia nitrogen indicates that the required flow rate of new water through the tank would be approximately 5,600 gallons per hour (93 gallons per minute) to maintain the desired ammonia nitrogen concentration. Even at this high flow rate, the system would also require aeration to supplement the oxygen added by the new water. A production system that uses water only once is referred to as a flow-through system.

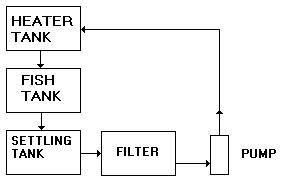

Recycling vary in design, but they

all have three basic elements in common.

A tank or tanks for holding the fish.

A water filter and

A pump to recycle the water.

Two other components are often

included;

A settling tank to remove the bulk of suspended solids.

A heater tank to even out the water supply to the holding tank.

The most important part of a system is the biological Filter. The health of the fish depends on the continiung efficient functioning fo the biological Filter.

The filter can only operate within the limits of its construction. It is often forgetten that the filter bed is just as much a living structure and dependent on theenviromental conditions as the fish in the tanks. It is composed of interacting bacteria, protozoa and other creatures. Recognizing some of the processes that take place in a filter bed and the way these are influenced by external factors is essential if the culturist is to get the most out of a recycling system.

The Filter Bed

We will talk about biological filters fot the farm because they are the simplest means of maintaining water quality. There are other types offilters but they are expensive and more difficult io maintain. All biological filters have a mixed population of bacteris whose joint action breaks down the organic and inorganic wast expelled bt the fish. These wastes may be solid or soluble and the filter must be able to cope with both types.

The principal soluble wast product of fish is ammonia excreted by the gills. In addition, small amounts of other substance like uren are released, but these rarely build ou hazardoud levels. All these wast are end products of nitsogen metabolism, and repesent a way the fish can dispose of nitrogen safely under normal circumstances.

However a recycling system does not constitute normal circumstances. Its water does not offer an infinite diluting capacity.

Decompostion of faeces and un eaten food allowed to remain in the system tends to relese such bound nitrogen as toxins like ammonia. The most important action of a biological filter is the conversion of harmful nitrogenos componds, principally ammonia, to less poisonous substance.

The harmless forms are nitrate and free nitrogen, mostly nitrate. The formation of nitrate in a biological filter is associated with two species of bacteria, Nitrosomas and Nitrobacter. In the presence of oxygen, Nitrosomas converts ammonia to nitrite, which is then oxidised to nitrate by Nitrobacter. The presence of oxigen is essential for these vital reactions cooure.

The filter must be constructed so as to ensure adequite oxygenstion at all times. If this reaction should be slowed or stopped by an absence of oxygen, Ammonia will quickly build up to a dangerous level and threaten the fish.

Other factors such as PH and temperature affect the nitrate formation to a lesser extent.

Since The rate of removal of amonis and other toxins will be in proportion to the numbers of bacteria in the filter. The greater the surface area of the filter bed meterial, the more bacteria will be in the bed. For this reason, filters are usually constructed of gravel and/ or crushed shells, because these substances nahe larger surface area compared with theit volume. Angler gravle will be more effectnt than founded, smoth pebbles.

Because the bactera removes oxygen from the water as it passes them, there will be progressively less dessolved oxygen in successive depts of a flooded filter bed. So it is better to have a filter that has a large sorface area, and is relatively shallow.

Submerged Filters

These are simple to build and are commonly used. They

consist a shallow tank containing the filter medium supported on

perforated filter plate. The filter medium is at all tiles

flooded. To mantain oxygenation through out the bed, water is

pumped theough at a fairly high flow rate. The recommended gragle

size for these filters is 2 - 5 mm.

Trickling Filters

These are well able to cope with hilg population

loadings but only have a low through out put of water. The

advantage of this filter is their good oxigenation at all levels.

The filter water exist as a film over the surface of the filter

media, the intrestices though the rest of the bed containning

air. The diffusion of oxigen into the water therefor occurs

throughout the whole filter bed.

Other Factors that affect

the Operation of Filter Beds

The over all tempratuer for growth of nitrifying

bacteria is in the range of 28 - 36 degrees C ( 79 - 98 degrees

F). So the conversion of ammonia to nitrate will proceed more

rapjdly as timperatures increase. A worm water recycling system

containing Tilapia, for example, is more able to cope with a

higher level of ammonia for a given filter area than a cold water

system containing Trout.

The PH plays a very important part in the filter. When a filter is first put into operation, The bacteria population takes some time to establish and in the meantime certain product accumulate. Ammonia accumlates first, and reaches a peak after a few days as the population of Nitrosomas increases. As the Amonia centration falls, nitrite builds up until Nitrobacter can oxidise it to nitaite. Both amonia and nitrite are highly toxic to fish. The toxicity of ammonia depends is pH dependent. Falling pH increases the proprtion of ionised ammonia which is less toxic to fish. Nitrite constrations above 0.4ppm are toxic and above 0.012 is thought to inhibit growth.

The total amount of unionized ammonia should be kept brlow 0.01ppm. The most desirable pH range is 7 to 7.5

Excess build up of nitrates is also undesirable, but a reasonable inflow of freshwater into the recycling system (1 - 2% of the systems volume per dat) usually keeps nitrates at an ecceptable level.

Sedimation Tanks

Build up of organic metter - fish faeses and food residues - has

a deleterious effect on the operation of a filter. It can clou

the spaces between the filter media, causing local deoxygenation

and un even flow through the filter bed. It also favers the

development of heterotphic bacteria with a reduction in the rate

of nitrifaction.

Fish Tanks

Fish tanks may be constructed of a host of meterials such as

fiber glass, concrete, corrugated irin, plastic, wood or a simple

hole in the groung with a plastic liner. As long as thet are

durable and hold water and fish. If they ate raised off the

groung adequate support must be supplied because water is very

heavy - one gal. of water weighs about 7.5 lb.